CAPABILITY

What Is Pcb? Comprehensive Understanding Of The Printed Circuit Boards

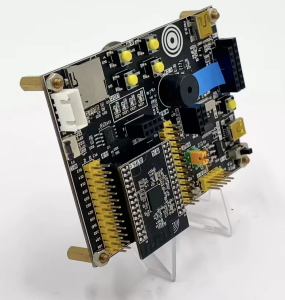

Printed Circuit Board (PCB) is an indispensable and important component of electronic products. It is the carrier of electronic components and circuit interconnections. PCB provides fixed support and electrical connections for electronic components so that electronic equipment can work properly. As the “skeleton” and “blood” of electronic products, PCB plays a pivotal role in modern electronic technology. Let us have a comprehensive understanding of what PCB is, as well as its structure and applications.

Basic structure of PCB

PCB consists of 3 basic parts: insulating substrate, conductive lines and holes.

Insulating substrate: the “skeleton” of PCB. Usually made of fiberglass reinforced epoxy resin (FR-4), which has good mechanical strength, heat resistance and insulation.

Conductive circuit: Copper foil circuit printed on the substrate, used to provide power and signal transmission to electronic components. The layout design of conductive lines determines the structure and performance of the circuit.

Holes: Connect the conductive lines on the upper and lower layers through the holes on the substrate to achieve electrical interconnection. The holes are electroplated with copper to form conductive paths.

Depending on the number of conductive layers, PCBs can be divided into single-sided boards, double-sided boards and multi-layer boards. Single-sided boards have only one layer of conductive lines, double-sided boards have one layer of conductive lines on the upper and lower sides of the substrate, and multi-layer boards have three or more conductive layers. Multilayer boards enable more complex circuit layouts and higher levels of integration

PCB manufacturing process

The manufacturing of PCB is usually divided into the following main steps:

Copper foil coating: Copper foil is covered on an insulating substrate to form a conductive layer.

Pattern etching: Use photolithography process to transfer circuit patterns on copper foil, and then perform chemical etching to remove excess copper foil, leaving the required conductive lines.

Drilling: Drilling holes where required to achieve connections between conductive layers.

Plated holes: Copper electroplating is performed in the drilled holes to form conductive paths.

Surface treatment: Surface treatment on conductive circuits, such as tin deposition, nickel gold plating, etc., to improve conductivity and anti-corrosion.

Coating with solder mask ink: Coating solder mask ink on the surface of conductive circuits to provide insulation protection.

Mounting components: Mount electronic components onto the PCB and solder them to fix them.

Manufacturing high-quality PCBs requires precise process control and strict quality management to ensure the reliability of PCBs during production, assembly and use.

PCB application areas

PCB is widely used in various electronic products and is the basis for the development of electronic technology. Main application areas include:

Consumer electronics: mobile phones, computers, stereos, cameras and other electronic products widely used in daily life.

Industrial control: electronic control systems in factory automation equipment, industrial robots, CNC machine tools and other industrial fields.

Communication equipment: routers, switches, base stations and other communication network equipment.

Automotive electronics: automotive engine control systems, airbags, in-car entertainment systems, etc.

Aerospace: high-tech electronic systems such as artificial satellites, spacecraft, and fighter jets.

Medical equipment: CT scanners, electrocardiographs, ultrasonic diagnostic machines and other medical diagnostic and treatment equipment.

With the rapid development of electronic technology, PCBs are evolving towards thinner, smaller, and multi-layered designs to meet the increasingly complex design needs of electronic products. In the future, PCB will play a more important role in various fields.

Phoenix Pcb is a professional printed circuit board supplier in China, our PCB products with high quality and a more competitive price, welcome to contact us!